-

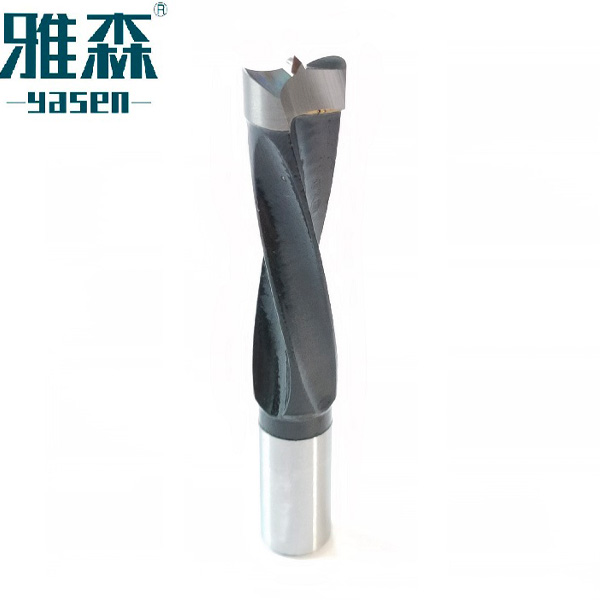

Carbide e phunya hlooho ka lesoba bakeng sa mochini o tenang oa mapolanka

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Kopo:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

-

tungsten carbide drill bit ZY-V bakeng sa ho betla mapolanka YASEN sesebelisoa sa setsebi sa mapolanka

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z1) -1spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Kopo:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho phunya masoba ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa e entsoeng ka laminated.

-

likotoana tsa ho cheka li-tungsten carbide bakeng sa phanele ea khekhe ea linotsi ea aluminium

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Kopo:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

-

57MM/70MM Kakaretso ea Bolelele ba Li-Dowel tse Tiileng tsa Moruo

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

-

CNC Machining KJ2-A Tungsten Carbide Flute Dowel Drills

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

-

Carbide e nang le ntlha ea V-point bits ka har'a lesoba bakeng sa mochini o tenang oa mapolanka

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho phunya masoba ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa e entsoeng ka laminated.

-

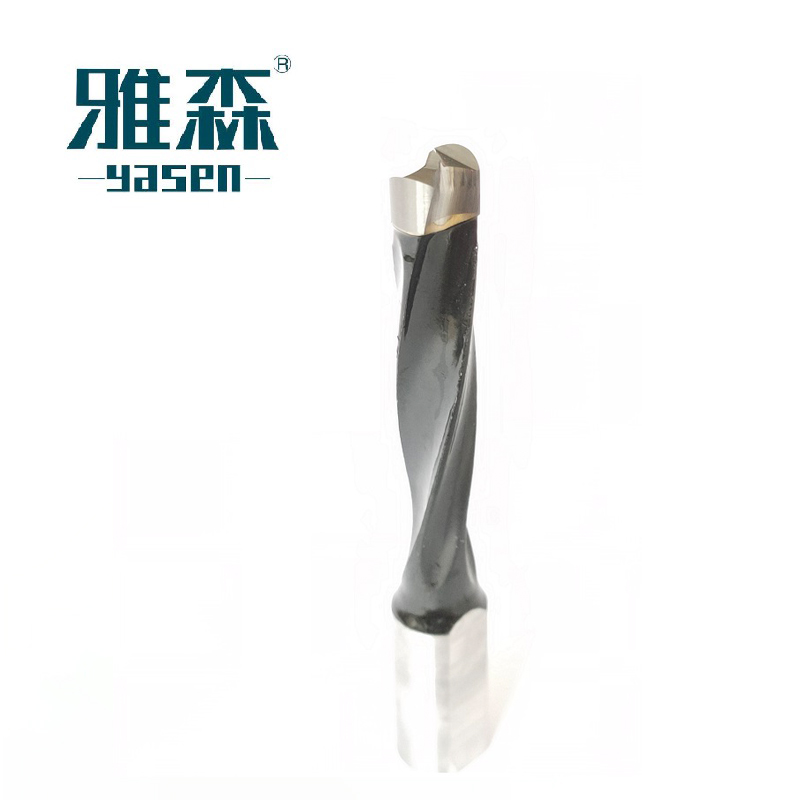

ZY Carbide brad point boring drill bakeng sa boro ea mapolanka

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

ZY drill bits ke lisebelisoa tse tsebahalang haholo tsa mapolanka tse phatlalalitsoeng ke k'hamphani ea rona.Moralo o kopaneng o holileng le setaele se bonolo sa spiral ke litšoaneleho tsa likotoana tsena tsa boro.

Li-drill tsa ZY li na le tungsten carbide e nang le chelete e ngata haholo.Tungsten carbide e sebelisoa moo e hlokahalang haholo, Ho feta moo, tšepe e boetse e tingoe ho finyella ho tiea ho ka tšeptjoang.Ka liteko tse se nang palo, re fumana angle e nepahetseng ka ho fetisisa bakeng sa ho sebetsa ka mapolanka.Haeba u na le litharollo tse ling tse ntle, re fana ka lits'ebeletso tse ikhethileng.Litšebeletso tse ikhethileng le tsona li etselitsoe boholo.Theknoloji ea plug in welding e boetse e etsa hore alloy e se ke ea oa.

-

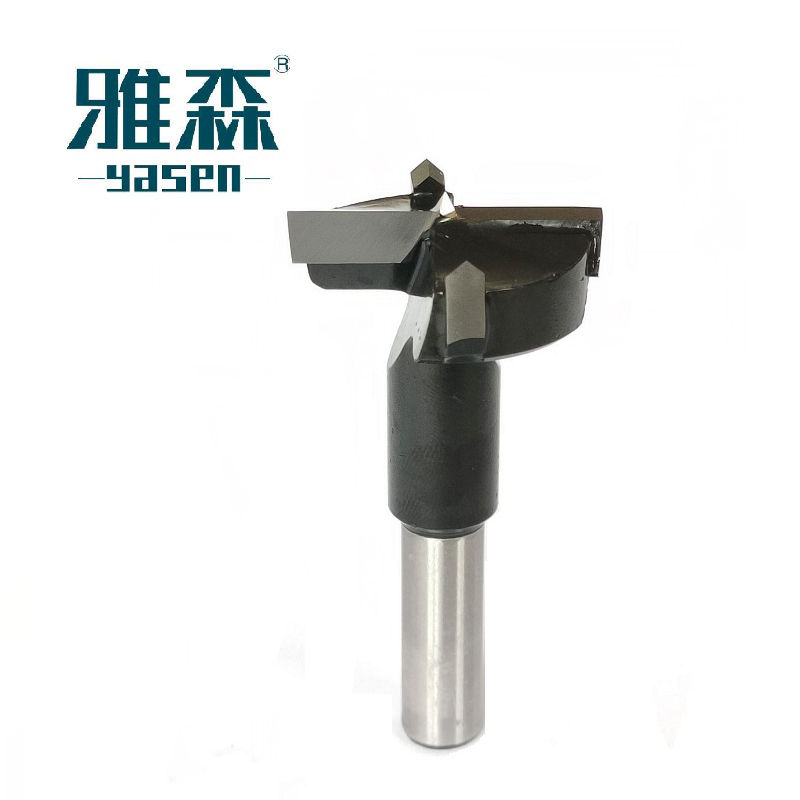

FT hinge boring forstner drill bits bakeng sa lesoba le leholo

Lintlha tsa Tekheniki:

- Tšepe e matla haholo

- Karolo e sehang e koahetsoeng ka lamunu kapa e ntšo

- Hlooho ea TCT e nang le ntlha e nepahetseng e leka-lekaneng bohareng.

- 2 ka nepo fatše cuttiong mathōko(z2).

- Shank e tšoanang e nang le sekoti sa ho khanna se bataletseng le se ka fetolehang.

Kopo:

E loketse li-hinges

E sebelisoa ka mechini e tenang e nang le li-chunks kapa li-adapter.

E sebelisetsoa ho cheka masoba a foufetseng a nepahetseng le a hloekileng a MDF, plywood, laminated, lehong le thata le le bonolo.

-

Likotoana tsa ho cheka tsa CNC KJ1

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

Li-drill bits tsa KJ-1 ke lihlahisoa tsa rona tse hlahelletseng tse entsoeng ka mechini ea machining ea 5-axis.

Likotoana tsa ho cheka tsa KJ-1 li entsoe ka ntlha ea drill ea tungsten carbide, 'mele oa ho phunya carbide ea tungsten le shank ea tšepe.Ha e le mokhoa oa ho tjheseletsa, KJ-1 e boetse e amohela welding e tšoanang ea plug-in joalo ka TCT.Hobane likotoana tsa ho cheka tsa KJ-1 li hloka ho jara torque e eketsehileng, plug-in welding e ka eketsa sebaka sa ho tjheseletsa ho netefatsa botsitso bo akaretsang ba borokho.Ka mokhoa o ts'oanang, e le ho fihlela litlhoko tse fapaneng tsa ts'ebetso, re boetse re sebelisa carbide e fapaneng ho tloha ho KJ-1 ho ea ho KJ-2 le ZY.

-

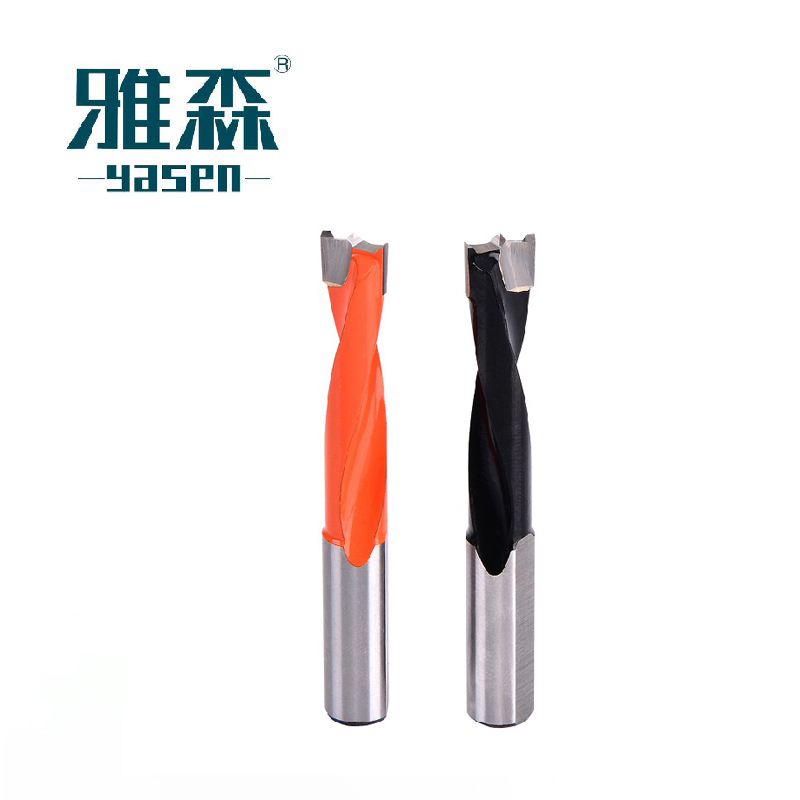

KJ2 CNC tungsten Carbide head blind-hole dowel drills

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

Li-drill bits tsa KJ-2 ke lihlahisoa tsa rona tse sebelisoang haholo tse entsoeng ka mechini ea machining ea 4-axis.

Li-drill tsa Brad point tse etselitsoeng ka ho khetheha ho rema lehong, li-drill tsa brad point li ka nqane lipakeng tsa liboro tsa spade bit sand twist.The shaft ea boro e tšoana le poropo e sothang, e nang le likanale tsa chip tse phaphametseng tse pota-potileng moqomo.Boholo ba ho itšeha ke ho etsa makhethe molomong oa likanale, empa lesoba le hlile le qalisoa ka ntlha e nyane - bophara ba brad (kapa spur) e isang shaft ka sekoting.Li-spur tse ling tse peli li ne li lutse pheletsong e ka ntle ea boro li thusa ho boloka boro inthaneteng.Hangata likanale li chesoa ka botebo holim'a li-drill tsa brad tse holim'a li-drill tsa twist, e le ho hloekisa litšila tsa patsi.E loketse mechine ea mapolanka ea CNC.

Ho boetse ho na le mefuta e 'meli ea mantlha bakeng sa li-drill tsa KJ-2 bits–brad point le V boring bits.