-

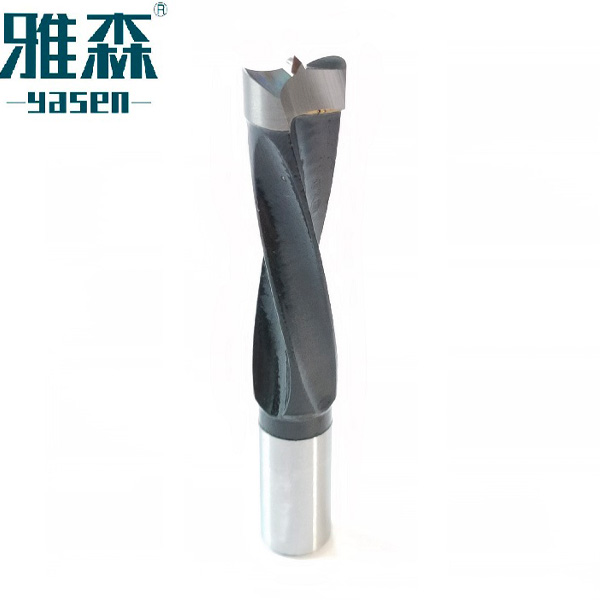

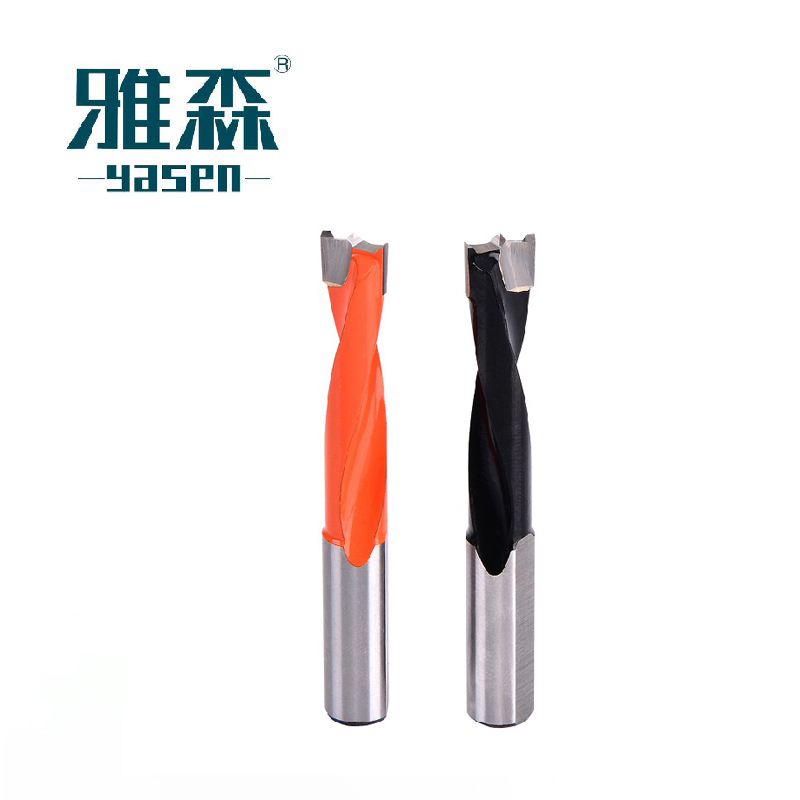

CNC Machining KJ2-A Tungsten Carbide Flute Dowel Drills

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

-

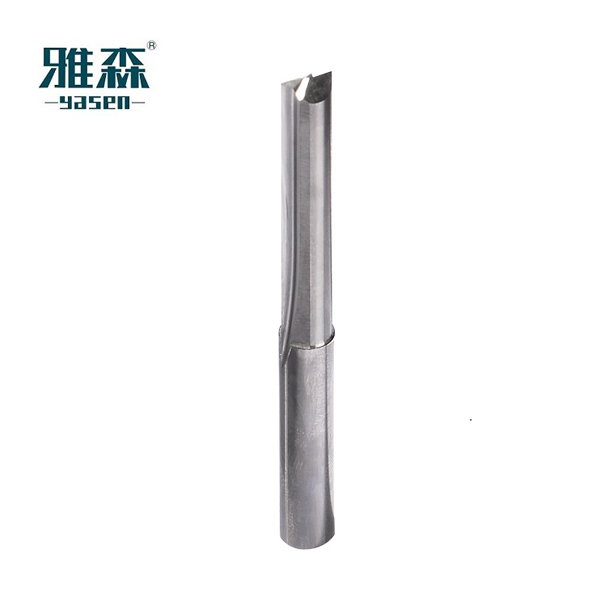

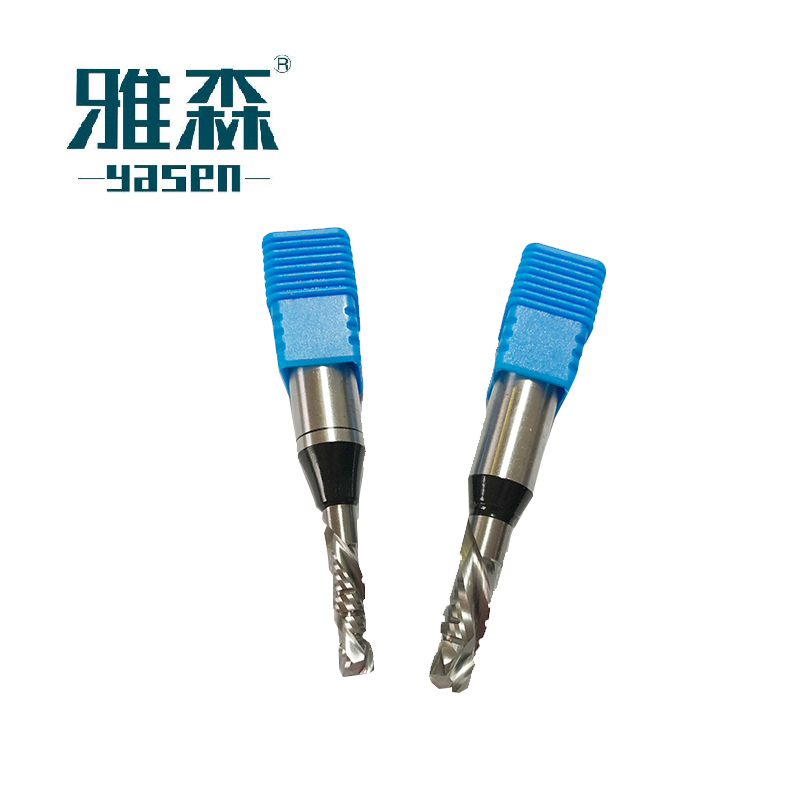

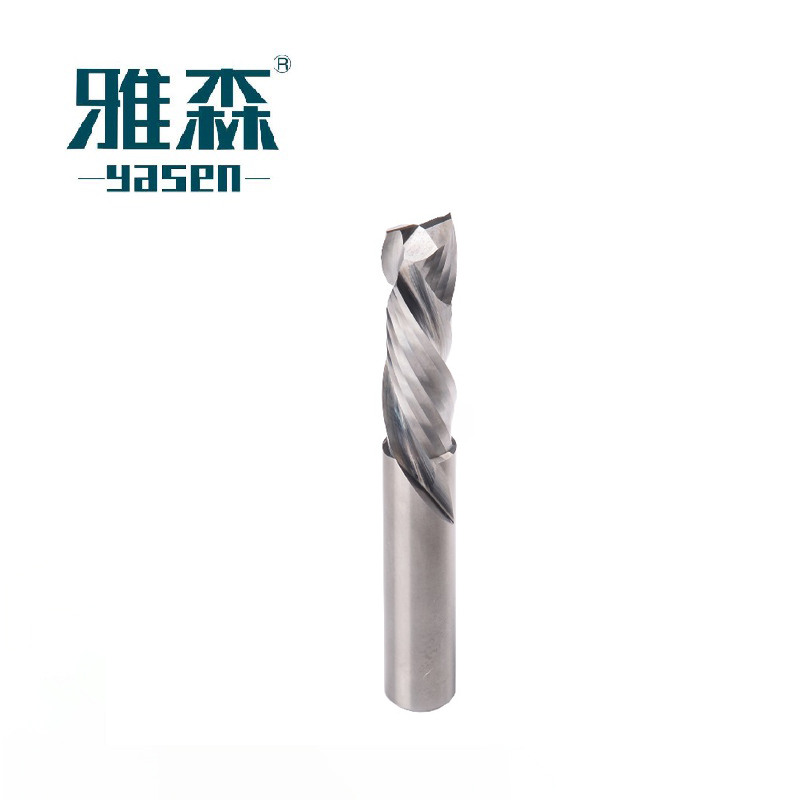

2 Flutes Solid Carbide Spiral Bits-Up End Mill Cutter

Lintlha tsa Tekheniki:

- Tungsten Carbide ea boleng bo holimo

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Kopo:

Bakeng sa pheletso e ntle ka lehlakoreng le ka tlase la laminate le melamine, e ka sebelisoa le ka mapolanka a thata le likarolo tse ling tsa lehong.

Bakeng sa litefiso tse potlakileng tsa phepelo ho li-routers tsa CNC, litsi tsa mochini le ho supa mechini ea ho tabola, ho etsa boholo ba liphanele, ho tsamaisa template le lits'ebetso tse ling tsa ho tsamaisa.

The integral cemented carbide bit e entsoe ka thepa e ntle e entsoeng ka samente e entsoeng ka carbide, e koahetsoeng ho liehisa bophelo ba tšebeletso. Thepa ea li-cutter bits ke likaroloana tsa ultrafine tsa tungsten tšepe.ho nepahala ho phahameng, ho tiea ho hotle, ho nchocho le ho khabisoa ke litšobotsi tse hlahelletseng tsa Yasen.Karolo e ka thōko e entsoe ka karolo e le 'ngoe ke grin e feletseng ea taolo ea digitalder.Re nka bar e ntle ka ho fetisisa ea tungsten tšepe e pota-potileng indastering, mme ts'ebetso ea welding ea mocheso o tlase e netefatsa boleng ba weld.Ts'ebetso ea ts'ebetso ea CNC ho netefatsa tlhahiso ea lihlahisoa tse nepahetseng le tsa boleng bo holimo.Lisebelisoa tse ntle haholo, tse tsoetseng pele, tse sebetsang li eketsa bophelo ba eona ho makhetlo a 3-5 ho feta li-router tse ling tse tloaelehileng.

-

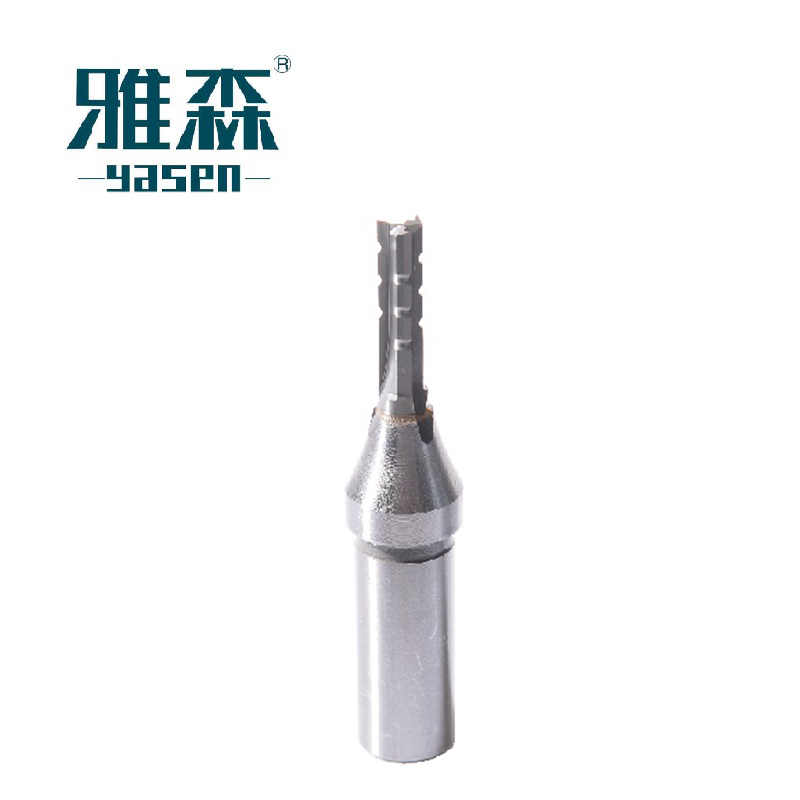

CNC Machining Carbide 2 Flutes Straight End Mill Cutter

Lintlha tsa Tekheniki:

- Tungsten Carbide ea boleng bo holimo

- Lithako tse 2 tse otlolohileng (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Kopo:

Bakeng sa pheletso e ntle ka lehlakoreng le ka tlase la laminate le melamine, e ka sebelisoa le ka mapolanka a thata le likarolo tse ling tsa lehong.

Bakeng sa litefiso tse potlakileng tsa phepelo ho li-routers tsa CNC, litsi tsa mochini le ho supa mechini ea ho tabola, ho etsa boholo ba liphanele, ho tsamaisa template le lits'ebetso tse ling tsa ho tsamaisa.

Sliver fiber welding ka mocheso o tlase.

-

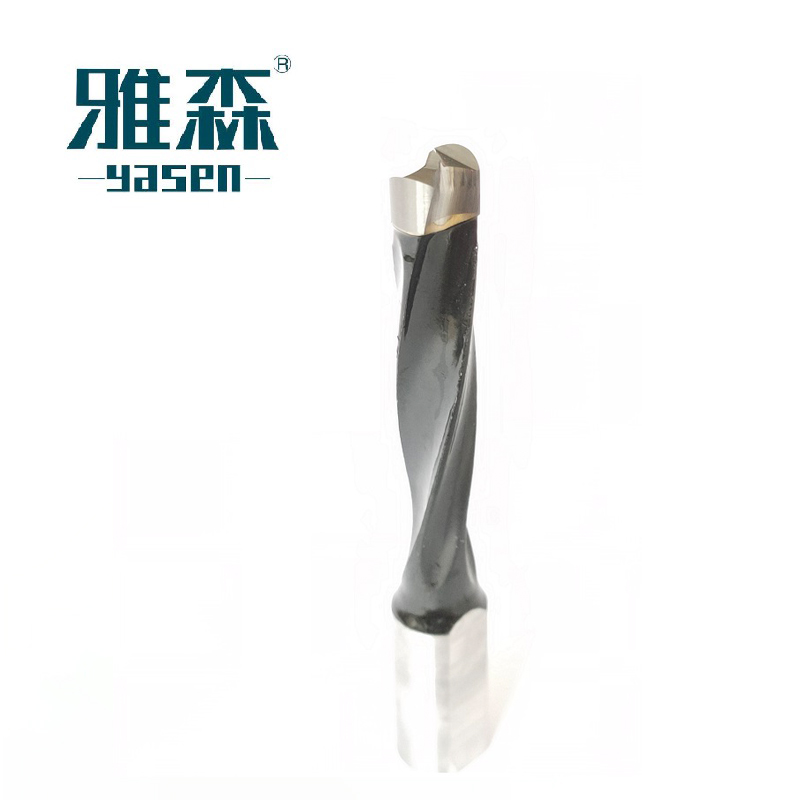

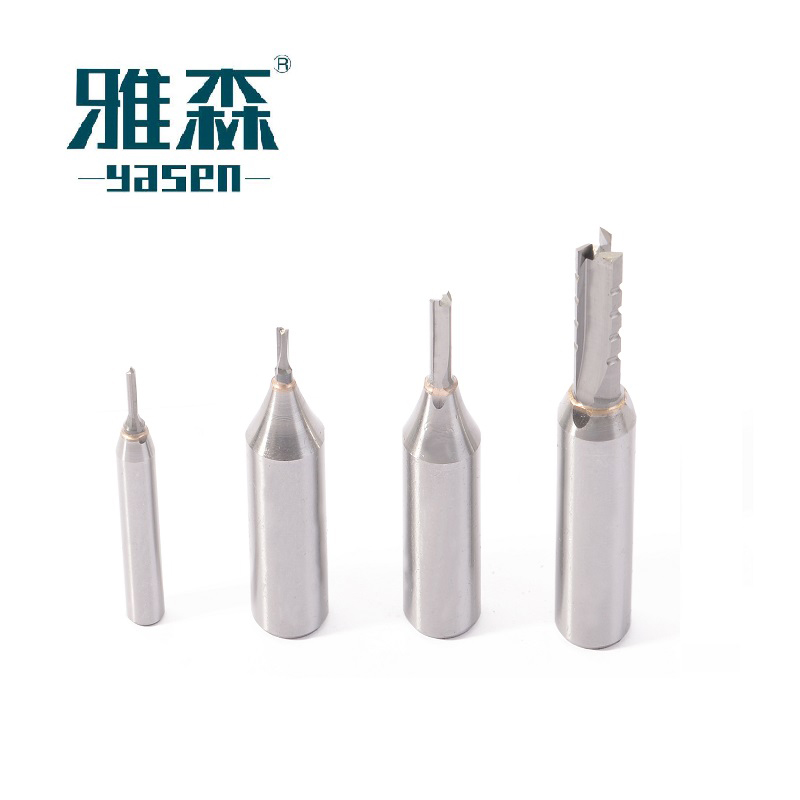

Tungsten Carbide Single Flute Bits CNC Machining End Mill

Lintlha tsa Tekheniki:

- Tungsten Carbide ea boleng bo holimo

- 1 spiral cutting edges(Z1)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Kopo:

Bakeng sa pheletso e ntle ka lehlakoreng le ka tlase la laminate le melamine, e ka sebelisoa le ka mapolanka a thata le likarolo tse ling tsa lehong.

Bakeng sa litefiso tse potlakileng tsa phepelo ho li-routers tsa CNC, litsi tsa mochini le ho supa mechini ea ho tabola, ho etsa boholo ba liphanele, ho tsamaisa template le lits'ebetso tse ling tsa ho tsamaisa.

-

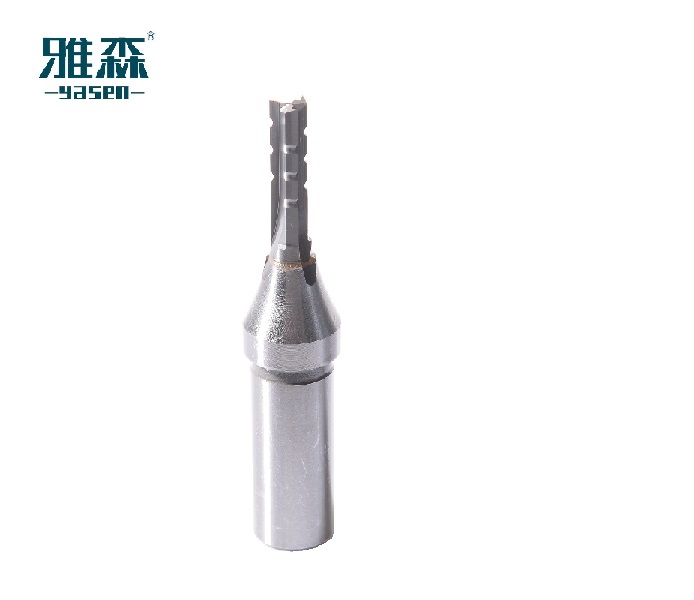

TCT Straight 3 Flutes Slotting Bits with Teeth CNC End Mill Bit

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 3 tse otlolohileng (Z3)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

-

Carbide e nang le ntlha ea V-point bits ka har'a lesoba bakeng sa mochini o tenang oa mapolanka

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho phunya masoba ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa e entsoeng ka laminated.

-

KJ2 CNC tungsten Carbide head blind-hole dowel drills

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

Li-drill bits tsa KJ-2 ke lihlahisoa tsa rona tse sebelisoang haholo tse entsoeng ka mechini ea machining ea 4-axis.

Li-drill tsa Brad point tse etselitsoeng ka ho khetheha ho rema lehong, li-drill tsa brad point li ka nqane lipakeng tsa liboro tsa spade bit sand twist.The shaft ea boro e tšoana le poropo e sothang, e nang le likanale tsa chip tse phaphametseng tse pota-potileng moqomo.Boholo ba ho itšeha ke ho etsa makhethe molomong oa likanale, empa lesoba le hlile le qalisoa ka ntlha e nyane - bophara ba brad (kapa spur) e isang shaft ka sekoting.Li-spur tse ling tse peli li ne li lutse pheletsong e ka ntle ea boro li thusa ho boloka boro inthaneteng.Hangata likanale li chesoa ka botebo holim'a li-drill tsa brad tse holim'a li-drill tsa twist, e le ho hloekisa litšila tsa patsi.E loketse mechine ea mapolanka ea CNC.

Ho boetse ho na le mefuta e 'meli ea mantlha bakeng sa li-drill tsa KJ-2 bits–brad point le V boring bits.

-

ZY Carbide brad point boring drill bakeng sa boro ea mapolanka

Lintlha tsa Tekheniki:

- Litšepe tse matla tsa boleng bo holimo + tungsten carbide

- STC spiral parts with center point -2 cutting edges (z2) -2 spiral flutes

- Li-spurs tse 2 tse kobehileng fatše (v2) -shank e ts'oanang e nang le sekoti sa ho cheka le bolelele bo feto-fetohang.

Aptlhaloso:

E sebelisoa mecheng ea borata kapa ka likotoana bakeng sa ho cheka masoba a foufetseng ka lehong le tiileng, metsoako ea lehong, plywood, lehong le thata le le bonolo le thepa ea laminated.

ZY drill bits ke lisebelisoa tse tsebahalang haholo tsa mapolanka tse phatlalalitsoeng ke k'hamphani ea rona.Moralo o kopaneng o holileng le setaele se bonolo sa spiral ke litšoaneleho tsa likotoana tsena tsa boro.

Li-drill tsa ZY li na le tungsten carbide e nang le chelete e ngata haholo.Tungsten carbide e sebelisoa moo e hlokahalang haholo, Ho feta moo, tšepe e boetse e tingoe ho finyella ho tiea ho ka tšeptjoang.Ka liteko tse se nang palo, re fumana angle e nepahetseng ka ho fetisisa bakeng sa ho sebetsa ka mapolanka.Haeba u na le litharollo tse ling tse ntle, re fana ka lits'ebeletso tse ikhethileng.Litšebeletso tse ikhethileng le tsona li etselitsoe boholo.Theknoloji ea plug in welding e boetse e etsa hore alloy e se ke ea oa.

-

TCT CNC Compression router bits

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

TCT compression router bit ke mofuta o ntlafalitsoeng oa TCT o ipapisitseng le compression milling cutter.

Joalo ka sehahi sa milling, e boetse e etsoa ke sesebelisoa sa mochini oa 5-axis CNC.

Phapang ke hore a e entsoe ka alloy e khutšoanyane tlas'a tlhaloso e tšoanang, e fokotsang litšenyehelo le ho etsa hore theko e be e ntle haholoanyane.Ka nako e ts'oanang, welding ea TCT e boetse e fana ka khetho e eketsehileng ea boholo ba shank.A e na le sebaka se eketsehileng khethong ea litlhaloso le litheko.

-

CNC routa ea lehong ho sila Cutter

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tsa spiral (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

-

TCT CNC e otlolohileng lekolilo rauta likotoana tsa router

Lintlha tsa Tekheniki:

- Litšepe tsa boleng bo holimo tsa Tungsten Carbide+Strength

- Lithako tse 2 tse otlolohileng (Z2)

- Fana ka qetello e ntle ka lehlakoreng le ka tlase la workpiece

- Ejection ea holimo ea chip

Aptlhaloso:

E sebelisoa mochining o borang feela le lisebelisoa tsa ho phunya lithapo.

Sebelisa ho cheka mekoting ea lehong le tiileng, metsoako ea lehong, MDF, plywood, lehong le thata le le bonolo.

Li-router tsa TCT ke sehahi se seholo sa mapolanka Chaena.

Li-router bits tsa TCT ke mofuta o mong oa sehang se nang le lekolilo le otlolohileng.TCT ke e 'ngoe ke khutsufatso ea theknoloji ea welding.Re tjheseletsa sehatla sa carbide le shank ya tshepe mmoho.Kahoo e na le theko e tlase le khetho e pharaletseng bakeng sa boholo ba shanks.

'Me li-bits tsa TCT li na le litlhaloso tse ngata tsa tlhahiso ea bongata, kahoo re ka hlahisa le ho boloka thepa ka potlako.

-

CNC lehong compression milling cutter

Lintlha tsa Tekheniki:

- Super-micrograin carbide ea boleng bo holimo -2+2 spiral cutting edges (z2+2)

- E fana ka qetello e babatsehang ka lehlakoreng le ka holimo le ka tlase la workpiece

- The upcut e fana ka qetello e babatsehang moeling o ka tlase

- The downcut e fana ka qetello e babatsehang ka holimo holimo

Kopo:

Bakeng sa bohale bo babatsehang ka mahlakoreng a ka holimo le a ka tlaase a laminates le melamine e mahlakoreng a mabeli .E ka boela ea sebelisoa ka mapolanka a thata le plywood.

Bakeng sa litefiso tse potlakileng tsa phepelo ho li-routers tsa CNC, litsi tsa machining le mechini ea lintlha bakeng sa ho ripping panel sizeng template e tsamaisang ts'ebeliso e 'ngoe ea litsela.